6 Color FLEXOPRESS STACK TYPE

| Printing width (mm) | ||||||

| Mode | Size | 500 | 800 | 1000 | 1200 | 1400 |

| Color | 2, 4, 6, 8 color | |||||

| Printing Length (mm) | 200-900 | |||||

| Total Power (Kw) | 2 Color | 9 | 12 | 14 | 16 | 18 |

| 4 Color | 11 | 14 | 16 | 18 | 20 | |

| 6 Color | 18 | 21 | 23 | 26 | 28 | |

| 8 Color | 20 | 23 | 25 | 30 | 32 | |

- 3 Drive System Control Panel

- Operator interface touch screen at rewinder side.

- Print unit Control panel

- Shaftless Rewinder/Unwinder Unit

- Electronic Edge Guide System

- Pneumatic Infeed/Outfeed system

- Registration Control Horizontal/Cercumference

- Doctor Blade with ceramic Anilox Roller

- Motorized Web video inspection System

- Motorized ink pump system

- Electronic Line Shaft Technology

- Auto Tension Control with load cell at unwinder stand

SHAFTLESS Unwind & Rewind

Latest Devlopment of easy and Quick change of media over with shaftless and Electronic web Guidling system for shaftless unwind station.

Operator Interface

Master operator control panel and remote operator control panel consists touch screen operating interface facilitates ease in operation. Safety of operator, machine and electronic modules are achieved with the help of necessary hardware protection and intelligent software routines.

Web Tension Control

Direct web tension control by using three drive control system consists of Load cell based closed loop vector controlled individual AC frequency drives for (I) Unwind station (II) Main drive (III) Rewind station.

Unwind : Auto web tension control system by using vector controlled AC drive & motor

Main Drive : Vector controlled AC drive & motor

Rewind : Auto web tension control system by using vector controlled AC drive & motor

Printign Station

High Quality Ceramic Anilox Roller With double Close doctor chamber system able to high quality printing with Motorized Ink Pump

Ceramic Anilox Rollers: Robotic plasma coated and laser engraved with improved cell structure ceramic anilox rollers with quick change over

Chamber Doctor Blade: Specially designed chamber doctor blade group, ensure straight profile of the blade resulting in lesser chamber pressure, better print quality & longer anilox roll life.

Motorized Web Video Inspection System Motorized web video inspection system consists of high quality CCD color camera, Industrial PC & Monitor (facilitates sequential inspection of the lateral and entire print repeat of the web).

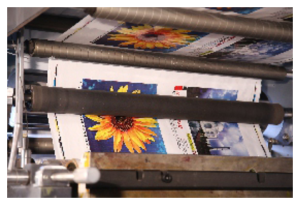

In-feed & Out-feed System (Draw unit)

The system mainly composed of matt chromium plated steel roller, and rubber covered nip roller with pneumatically adjustable pressure.

Drying & Exhaust System

Drying Chamber: Mainly consists of AC frequency drive controlled heavy-duty blower with connection duct and dampers to balance fresh and recycling air.

The optimized air flow, minimizes heat consumption and avoid solvent retention in the printed substrates.

Central Exhaust System: AC frequency drive controlled solvent extraction system to exhaust contaminated air from all the print stations through central duct.