Flexography Plate Making

Solvent Washout Plates

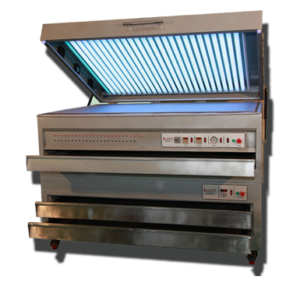

Special Features @flexo Photopolymer Plate making machine For Flexography Plate Making Equipment

Model : EDT(Exposure + Dryer + Treatment ) RW (Rotary washout)

@1600 :- @1600 EDT+RW ( 1.1 x 1.6 m )

@2001 :- @2001 EDT+RW ( 1.1 x 2.0 m )

@2002 :- @2002 EDT+RW ( 1.3 x 2.0 m )

Plates suitable : DuPont / Cyrel,Ohkaflex, Flex-Light, Asahi / AFP, BASF / Nyloflex, JET..

For printing : Label, film, paper, corrugated board, paper carton, knitting bag, Tetra pak etc. Exposure / Washout / Drying /Treatment (Light finishing) in complete functions.

- Instant light up Philips high intensity lamps

- Unique digital timers for back/main exposure

- Excellent lamps cooling / exhausting system

- Quick vacuum drawdown pump with indicator

- Flat washout unit 3 in 1 for easy access

- Special bristle good for all kind plates wash

- Automatic control of temperature precisely

- Excellent result for 200 LPI 1% reproduction

- Drying drawer with uniform heat distribution

- Temperature adjustable by a precise controller

- Unique air circulation and exhaustion design

- Over heat sensor for safety and protection

- Chemical free operation, simple, easy and save

- Digital timer for light finishing control

- Philips UVC high intensity lamps equipped

- With powerful air exhausting for big size models

- Unique digital timers for back/main exposure

- Instant light up Philips high intensity lamps

- Excellent lamps cooling / exhausting system

- Quick vacuum drawdown pump with indicator

- Drying drawer with uniform heat distribution

- Temperature adjustable by a precise controller

- Unique air circulation and exhaustion design

- Over heat sensor for safety and protection

@1600 EDT ( 1.1 x 1.6 m )

@2001 EDT ( 1.1 x 2.0 m )

@2002 EDT ( 1.3 x 2.0 m )

- Chemical free operation, simple, easy and save

- Digital timer for light finishing control

- Philips UVC high intensity lamps equipped

- With powerful air exhausting for big size models

| MODEL | UNIT | MEASUREMENT(cm) | N/W | G/W | WATT |

| @1600 EDT | EXPOSING+DRYING+TREATMENT | 187 x 175 x 103 | 950KG | 1150KG | 8KW |

| @2001 EDT | EXPOSING+DRYING+TREATMENT | 230 x 175 x 103 | 1100KG | 1300KG | 9KW |

| @2002 EDT | EXPOSING+DRYING+TREATMENT | 273 x 190 x 224 | 1800KG | 2200KG | 15KW |

- Rotary washout to save operating room

- Operation-watching window.

- Solvent tank equipped with level indicator

- Before-finish washout exhaustion design

- Indicator for brush

- roller distance

- Wrap-a-round washout gets better results

- Both solvent spray and steep type design

- Brush distance adjustable for any thickness lates.(Inside)

- Roller rotation and brush horizontal movements

@1600 EDT ( 1.1 x 1.6 m )

@2001 EDT ( 1.1 x 2.0 m )

@2002 EDT ( 1.3 x 2.0 m )

| MODEL | UNIT | MEASUREMENT(cm) | N/W | G/W | WATT |

| @1600 RW | ROTARY WASHOUT | 271 x 78 x 135 | 800KG | 1000KG | 2.5KW |

| @2001 RW | ROTARY WASHOUT | 215 x 100 x 141 | 900KG | 1100KG | 2.5KW |

| @2002 RW | ROTARY WASHOUT | 304 x 78 x 135 | 900KG | 1100KG | 2.5KW |